Traditional Mi’kmaq birch bark canoe building with Todd Labrador

Kejimkujik National Park and National Historic Site

The canoe is an iconic symbol of the Mi’kmaw cultural landscape and also of the contemporary experience of Kejimkujik. The Kejimkujik Birch Bark Canoe Project highlights the work of master Mi’kmaw craftsman, Todd Labrador, as he builds traditional birch bark canoes in Kejimkujik National Park and National Historic Site.

June 27 to September 7, 2024Public demonstrations

Thursday to Sunday

12:30 pm to 3:30 pm

The Kejimkujik Birch Bark Canoe Shop at the south end of Merrymakedge Beach. Follow the signs and the path.

Todd Labrador “AMALKAT SAM’QUAWNIJTUK”

(One who dances on water)

Todd is an internationally known Mi’kmaq artisan/birch bark canoe builder whose art can be found throughout North America and Europe. Raised on the Wildcat Reservation in Queen’s County, Nova Scotia, he grew up hearing stories from his father, Charlie, who was the first Chief for the Acadia First Nation.

Todd enjoys spending time with his friends and family and sharing his knowledge and skills. Todd creates art during the winter months and builds birch bark canoes during the summer months. He is forever grateful to all who have helped him throughout this journey.

Mi'kmaw style birch bark canoes

What makes the Mi’kmaw style canoe unique?

Mi’kmaq canoes were built with one gunwale on either side of the canoe, where many other types of bark canoes, such as Malecite, Ojibway, Anishinabek, were built using two gunwales on either side: the outwale and the inwale. Their canoe ribs were forced up and in between the gunwales, whereas the Mikmaq canoe rib ends were made blunt and shoved up behind the one gunwale and between the bark and the wood.

The Mi’kmaq canoe is also sewn with roots entirely from one end to the other, while many other canoes are sewn in approximately 2-inch intervals on the gunwale, leaving approximately a 2-inch space for the ribs.

Are there different types of Mi’kmaq canoes?

Generally, there were two designs for the Mi’kmaq canoe: the ocean-going canoe and the lake/river canoe.

Oceangoing canoes were approximately twenty feet or longer with a raised midsection on the gunwales. The longest one that Todd knows about was twenty-eight feet long. In 2022, the Labrador family built an ocean-going Mi’kmaq canoe at Kejimkujik for The Canadian Canoe Museum in Peterborough.

Lake/river canoes were less than twenty feet long with straight gunwales. Some of these canoes would have been nine feet long and made for a single person to use for trapping. These could be taken into narrow streams and portaged with ease.

How long do birch bark canoes last?

Birch bark canoes are very durable compared to a canvas canoe. They can last for a long time if cared for and maintained properly. Elders have told Todd that birch bark canoes can last as long and the person who owns the canoe.

What is the capacity of a canoe?

A sixteen-foot canoe would have been intended for two people, but would be capable of carrying four adults and several hundred pounds of cargo. The sides of the Mi’kmaq canoe were turned in slightly at the top to attach to the gunwales; this is known as tumblehome. Most other types of indigenous canoes were vertical or slanted slightly outward.

Building a Mi'kmaw style birch bark canoe

Where were traditional Mi’kmaq canoes built?

Traditionally canoes were built near a watercourse, such as a stream or a river or a lake. They were constructed on a gravel bed where wooden stakes could be easily driven into the ground.

Does taking the bark off kill the tree?

In Todd’s experience, removing more than four to six feet of bark from a live standing tree and cutting through the cambium (the inner bark), can cause a tree to die within two years or sooner, depending on the health of the tree. Todd has taken fifteen to twenty feet of bark off a live tree and the tree died within a year and the cambium cracked and started to fall off the tree. It is best to just cut the tree down and use the wood for making paddles, thwarts, or firewood. Todd says, “We are always told not to waste and to have respect for the gifts that our Mother Earth has provided for us.”

Spruce roots

Spruce roots are used to lash the bark together. Roots are harvested by hand in wet mossy locations, and boiled to remove the bark. After the bark is removed, the roots are split to the desired size. A

nineteen-foot lake canoe, for example, takes approximately 700 feet of split spruce root.

Ribs

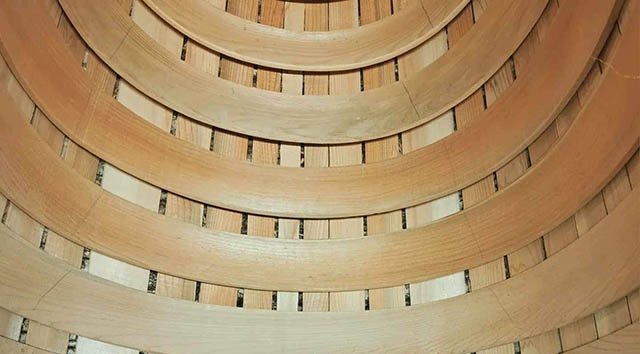

Ribs are lateral supports which provide hull rigidity and structural strength. Nova Scotian spruce was traditionally used for these, but Todd now uses clear cedar, as it is much easier to steam-bend.

Planking

Planking is the name given to the series of lightweight boards that run perpendicular to the ribs and provide support to the exterior bark.

Thwarts

Thwarts are a structural crosspiece attached to the gunwales and are usually made from hardwoods like ash, maple, white birch and yellow birch.

Wooden pegs

Wooden pegs are used to secure the gunwales and are usually made from hardwood like maple, but ironwood (hornbeam) also makes a strong peg. Todd’s father told him that dry spruce limbs can also make a very strong peg.

Planks

Planks are inserted at each end of the canoe to provide additional structural support. Before installing the planks, the ends of the canoe are filled with cedar chips to reinforce them since they are not supported by frames. These boards are made of cedar or hardwood and attach to a chord.

Sealant

Traditionally spruce gum (sap from the spruce tree) was used to seal gores and holes in the bark. It was harvested and boiled down to remove the moisture, then mixed with bear fat and ash as applied, while hot, to the seams of the canoe. Today Todd uses modern sealant, as it generally is more stable and lasts longer with less repair. Traditional gum may melt in hot temperatures.

Gunwales

Gunwales are the upper edge of the side of the canoe that is also used as a frame when starting the build. These are made from clear spruce, cedar, and sometimes hardwoods like ash, maple, white birch, and yellow birch.

Tree cambium

The cambium layer is the inner layer of bark growing closest to the actively growing tree trunk. The thin dark brown layer of cambium that is attached to winter bark can be etched on for creating designs.

Paddles

Canoe paddles were made from clear, straight wood, such as ash, maple, and sometimes clear softwood. However, softwood does not have as much strength and can snap more easily than hardwood.

- Date modified :